Standing on a busy street in a large city, you see dozens of tall office buildings lined in a row like in a cornfield. From the street, they are huge. The Sears Tower in Chicago, for example, is 1,453 feet high.

For this example, let’s stick with the Sears Tower. Each floor averages around 41,000 square feet in space. Of those 41,000 square feet, a minuscule portion determines whether people have time to escape in case of fire. How small are we talking about?

3 inches!

It sounds like I’m exaggerating. But I’m not. Maybe a little. The range is really 1- to 8-inches, but three sounds cool.

Curtain Walls

Curtain walls are exterior walls built on multistory buildings but aren’t part of the load-bearing structure. They’re the first line of defense from rain, wind, sun exposure, noise, and extreme temperatures. They offer advantages such as:

- Energy-Efficiency

- Transparency

- Flexible Designs

- Structural Stability

Although commercially used for over 30 years, the single mark against them was fire safety. Building codes initially included brief mentions of fire protection using curtain walls. Since there were no standards, designers, contractors, architects, and code officials used various and untested solutions.

Fire Danger

The architectural industry began recognizing the danger to buildings with curtain wall construction. Ordinary window glass shatters when heated above 250 ºF. For many years, polished wired glass was the only thing preventing shattering and pass NFPA 80. Although the glass looked secure, the only job of the wires was holding the glass in place during a fire. If the fire reached high enough temperatures, the glass shatters anyway, and the polished wire became dangerous shrapnel.

After significant fires in the United States and Mexico, code officials and suppliers sought to implement passive systems that contained a fire at the perimeter of the building. Eventually, manufacturers developed new fire-rated glazing materials, opening the door to several fire-rated glazing systems for consideration.

Spreading of the Fire

If a fire breaks out, the spread of the fire is vertical, following air currents. There are three primary ways fire spreads from floor-to-floor in high-rise buildings. (Refer to Figure 1)

Leapfrog: The leapfrog effect describes the vertical spread of fire in tall buildings around the building’s perimeter containment system. Material on an upper floor catches fire because of the flames and intense heat escaping from a lower window.

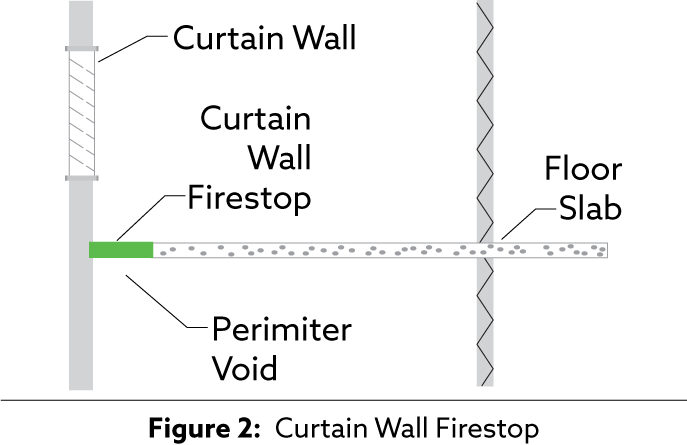

Voids: Fire spreading within the perimeter void space between the exterior curtain wall and the edge of the floor.

Cavities: Fire spreading within the concealed space of an exterior wall.

If trapped in a tall building on fire, it doesn’t matter how the fire may reach you; the concern is the effectiveness of the fire-stopping barriers between the flames and smoke and you. This is where curtain wall firestops become vital.

Fire Containment

Look at a three-legged stool. Three components are working together, making the stool functional: the seat, stabilizer, and legs. Removing one portion of these components weakens the integrity of the chair.

Following this analogy, the fire suppression system of a building, in theory, works the same way. The easiest way of extinguishing a fire, confining it in a single area.

Curtain Wall Firestops

The first and most critical component in a curtain wall system for containing a fire is a firestop. Curtain wall firestops usually consist of mineral wool and a firestop sealant. The wool is fire-resistant while the sealant seals the smoke.

The first and most critical component in a curtain wall system for containing a fire is a firestop. Curtain wall firestops usually consist of mineral wool and a firestop sealant. The wool is fire-resistant while the sealant seals the smoke.

Designers place firestops in joints between floors and interior walls where the floor and the wall each have a fire-resistant rating. (Refer to Figure 2).

Modern building codes require firewalls not only to block smoke and fire but also to stop heat from moving through the walls. These firestops enhance fire protection in large and high buildings requiring stringent fire-ratings between floors.

When all aspects of suppression work, firewalls, curtain wall fire stops, and an automatic sprinkler system reduce the threat posed by fire. If one element fails, the potential for catastrophe escalates because the fire spreads.

Fire-Rated Glazing Systems

Reviewing the definition of the fire-resistance rating is essential: the time a building element, component, or assembly maintains the ability to confine a fire, continues to perform a given structural function or both.

The evolution of fire-rated glazing systems evolved to where architectural firms have a choice of several fire-rated options. Here are four such systems:

Fire-Rated Curtain Wall Systems

This curtain wall system uses transparent glass wall panels having heat blocking capabilities. Manufacturers follow many methods, so their glass products pass fire tests while staying reasonably cool on the non-fire side of the glass.

Another aspect of fire-rated curtain wall systems uses fire-resistant framing materials. Using roll-formed thin gauge steel coils, engineers build narrower frames, achieving almost any finished look.

Silicone-Glazed Systems

These systems combine fire-resistant glass, attached to narrow steel fire-rated frames, with silicone sealants. This assembly eliminates the need for pressure plates or caps. Current silicone glazing systems are available with up to 120-minute fire ratings.

Butt-Glazed Systems

These systems allow engineers to achieve a frameless look, yet keep fire safety at the forefront. They get their continuous look by using fire-resistant rated glass wall panels butt-glazed using a silicone sealant. They secure these panels within heat-resistive frames.

Fire-Rated Glass Floor Systems

Recent developments have given architects the option to use fire-rated glass floor systems. This option works in areas needing a code-approved fire barrier between the floors of a building. An added benefit is allowing daylight to penetrate multiple levels.

Some fire-rated glazing systems provide several benefits, yet are better suited for specific projects. Projects that may have better applications include:

the application must defend against transferring flames, smoke, and heat

the assembly is expected to exceed 25% of the total wall area

visual continuity with non-rated systems is integral to the success of the project

it is crucial to bring daylight deep with a building’s core

fire-rated glazing with multi-functionality is required

The most significant benefit of using fire-rated glazing systems is meeting code requirements. When testing all the components using the same standards, the system provides an added layer of protection.

In Sum

When looking at the beautiful skyline of a larger city, you’ll see some stunning architecture that wasn’t possible a few years ago. Curtain wall systems have given designers more latitude than ever before. But with brilliant design comes great responsibility. There is a multitude of ways a failure in one safety aspect leads to disaster.

However, when meeting all local, state, and federal codes and working with fire suppression systems curtain wall systems decrease the odds of catastrophic building failures.