China currently produces over 90% of the world’s supply of rare earth elements (REE), which it has controlled for decades, leaving many outside the industry questioning their viability as a source and whether they will continue to be an important resource in the future.

In response to trade restrictions imposed on Chinese raw materials, the U.S. Department of Commerce started a program to identify new suppliers of these minerals. They found many untapped sources of rare earth elements within the United States, with over 400 known deposits across multiple states.

The problem is that many of these reserves remain unmined due to low demand and high mining costs. As such, the United States must address several challenges before mining can begin on a large scale again.

Rare Earth Elements

There are 17 rare earth elements (REE), which are all metals. Before 1965, most of the world's REE supply was due to mining in South Africa, India, and Brazil. REEs are considered the vitamins of chemistry:

They help everything perform better, and they have their unique characteristics," he says, "particularly in terms of magnetism, temperature resistance, and resistance to corrosion.

Because these 17 elements were hard to extract from surrounding matter, they were named 'rare earth." The name is a misnomer; the United States Geological Survey describes REE as 'moderately abundant.' Although not as common as other elements like silicon and iron, many locations worldwide have REEs in the ground.

Because these 17 elements were hard to extract from surrounding matter, they were named 'rare earth." The name is a misnomer; the United States Geological Survey describes REE as 'moderately abundant.' Although not as common as other elements like silicon and iron, many locations worldwide have REEs in the ground.

Writing at The Verge, James Vincent illustrates how common cerium is:

The rare earth element cerium, for example, is the 25th most abundant on Earth, making it about as common as copper. But unlike copper and similarly well-known elements, such as gold and silver, rare earths don't clump together in single-element lumps. Instead, because of their similar chemical composition (15 of the 17 rare earth elements occupy consecutive places on the periodic table), they bond freely with one another in minerals and clays.

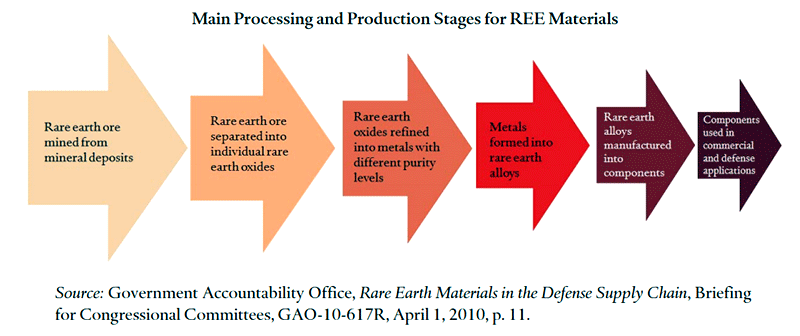

The process of extracting REEs from other compounds takes time. Material, having been mined, is repeatedly dissolved in acids, filtered, then dissolved again. Vincent quoted rare earth trader and journalist Tim Worstall when he said, "the whole process is 'expensive, difficult, and dangerous."

China

Enter China. During the late 1980s, China emerged as the world's leading REE producer. China rose to the top because of the combination of low-cost mining and chemical extracting methods and lax environmental restrictions. Worstall said China's biggest REE plant is an iron ore mine extracting REEs on the side. This allows the Chinese to take advantage of multiple products from a single source.

No country could compete with China's labor costs, so between 2011 and 2017, China produced about 84% of the world's supply of REE.

The match lighting the fuse resulting in an explosion of demand for REE, was color television. Europium became essential for color images. The US became the leading producer of europium because the Mountain Pass Mine became the leading source of the element.

List of Rare Earth Elements

For reference, the table below lists each REE, its Atomic Number, and its common uses:

| Element |

Symbol |

Atomic Number |

Example Applications |

| Light rare earth elements |

| Lanthanum |

La |

57 |

Optical glass, nickel-metal-hydride batteries |

| Cerium |

Ce |

58 |

Colored glass (flat-panel displays), automobile catalytic converters |

| Praseodymium |

Pr |

59 |

Super-strong magnets, metal alloys, specialty glass, lasers |

| Neodymium |

Nd |

60 |

Permanent magnets |

| Samarium |

Sm |

62 |

Permanent magnets, nuclear reactor control rods, lasers |

| Europium |

Eu |

63 |

Optical fibers, visual displays, lighting |

| Gadolinium |

Gd |

64 |

Shielding in nuclear reactors, X-ray and magnetic resonance imaging scanning systems |

| Heavy rare earth elements |

| Terbium |

Tb |

65 |

Visual displays, fuel cells, lighting |

| Dysprosium |

Dy |

66 |

Permanent magnets, lighting |

| Holmium |

Ho |

69 |

Lasers, high-strength magnets, glass coloring |

| Erbium |

Er |

68 |

Glass coloring, fiber optic cables |

| Thulium |

Tm |

69 |

Lasers, portable X-ray machines |

| Ytterbium |

Yb |

70 |

Stainless steel, lasers |

| Lutetium |

Lu |

71 |

Petroleum refining |

| Yttrium |

Y |

39 |

Metal alloys, visual displays, lasers, lighting |

China Flaunting Power

In 2010, China produced approximately 97% of the world's supply of REE. In September of that year, an incident between the Japanese coast guard and a Chinese fishing trawler led to the detention of the fishing captain.

China's response? They announced a stop to all REE shipments to Japan. Since Japan produces many high-tech products, they released the captain straightaway.

As a result of this incident, the US determined that China used its near-monopoly of REE as an economic weapon.

Fortunately, Eugene Gholz, an associate professor at the University of Texas at Austin, determined that China's embargo didn't damage the availability and the REE's market as initially thought.

Unfortunately for China, despite REEs' headline-grabbing role in so many high-tech industries, temporarily suspending exports cannot impose acute cost on even seemingly vulnerable targets like Japan. Why did the embargo not exact a greater cost on rare-earth dependent supply chains, either in Japan or in global markets? Why did it not manage to meaningfully deter Japan from asserting its territorial claims (beyond Tokyo's immediate, tactical decision to release the Chinese fishing boat captain)? The answer primarily traces back to three factors: increases in non-Chinese REE supplies that began well before the embargo, undermining China's supply-side leverage; administrative difficulties associated with enacting an embargo of this sort; and real-time adjustments in the market that circumvented the embargo.

In Sum

Although China has been the dominant producer of rare earth elements for over two decades, it isn't the only country enjoying access to these resources. Chinese energy demands have grown and developed new deposits and processes in other countries.

On the supply side, some of the most important sources of REE are in Russia, Australia, and Brazil. Also, several potential candidates for REE deposits have yet to be explored.

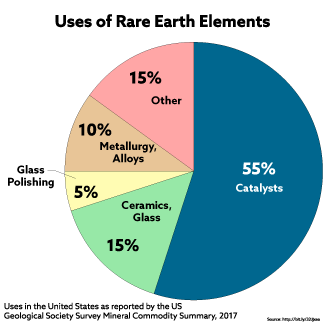

On the demand side, REEs are a key component of many products using high-tech components, including LCDs, hybrid cars, wind turbines, and defense systems. In recent years, these requirements have led to an increasing interest in developing countries—particularly in emerging markets like Africa and South America—in securing and using REEs.

At the same time, these changes have made it increasingly difficult for China to maintain its near-monopoly status in the global market for REE and other rare earth elements. The result will be an escalating price war, decreasing the metal's value.

The United States is already a major supplier of these materials and will probably soon become a major producer. The U.S. has many more potential REE deposits than China—most are in the West and Midwest, giving the U.S. a significant advantage over China in production.