Central Wisconsin Finishing

Ensuring the best finish means a thorough surface preparation. At CWF*, the adhesion and durability of the finish is something we pay close attention to. Fabricated parts prepared in a variety of ways, including:

- 9-Stage wash system

- Bake-off

- Shot blasting

When the components are ready, the seamless finish is the result of several, including:

E-Coating

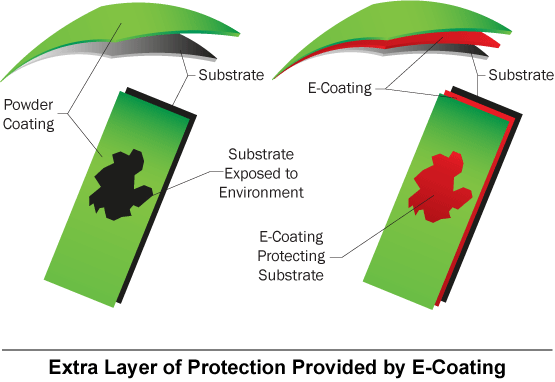

E-coating is a liquid finish that's an electrically applied paint coating. E-coating is a process where a fabricated part bathes in a water-based solution containing paint emulsion. Adding voltage causes the emulsion to bond to the piece.

Powder Coating

Powder coating involves spraying electrostatically charged particles to the surface of a component. Once applied, curing takes place in an oven causing the particles to melt and complete the chemical reaction producing the finish.

E-Coating vs Powder Coating

Comparing these two coating methods and saying one is better than the other isn’t fair. Each type of coating offers advantages over the other depending on the job.

Comparing these two coating methods and saying one is better than the other isn’t fair. Each type of coating offers advantages over the other depending on the job.

E-coating does provide these benefits:

- At times, its less expensive over powder coating

- Greater control over coating thickness

- Even finish

- Protection from corrosion

- Durable

- Strong adhesion

- Environmentally friendly

What can Schuette Metals do for you today?