Cement trucks are an essential part of any construction project, big or small. These massive vehicles carry the wet cement mixture from the batching plant to construction sites, which are used for various building applications. Cement trucks can be classified into two major types: the transit mixer and the volumetric mixer.

The transit mixer is a concrete truck that mixes and transports concrete from one location to another, while the volumetric mixer churns cement on-site as needed. These trucks are made up of several critical components that work together to ensure their optimal performance.

The transit mixer is a concrete truck that mixes and transports concrete from one location to another, while the volumetric mixer churns cement on-site as needed. These trucks are made up of several critical components that work together to ensure their optimal performance.

Understanding how these critical components function is vital for anyone who uses or works with cement trucks. This article will discuss three critical components of cement trucks: Pedestal Components, Drum Components, and Chassis Components.

We will cover each component in detail and explore its role in ensuring operational efficiency. By the end of this article, you will better understand how each component works together to make these massive machines work effectively.

Pedestal Components

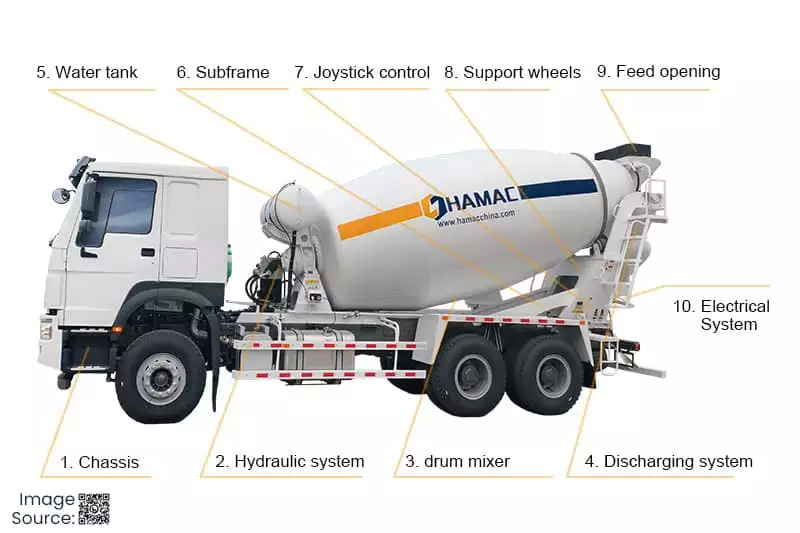

The pedestal is where all other critical components of a cement truck are mounted upon. It consists of several essential parts that work in tandem with other parts to ensure smooth operation.

One of those parts is the hydraulic system responsible for moving the pedestal up and down. The hydraulic system operates by pumping fluid into a closed container at high pressure; this makes it easier to lift heavy loads such as concrete mixers or dump trucks that weigh several tons.

Another important part is the bearings that allow for smooth drum rotation on top of which all other drum components sit. The bearings must be lubricated regularly to ensure long-lasting performance without jamming or breaking down in extreme conditions such as rough terrain or harsh weather conditions.

The support legs are another essential component because they provide stability when loading or discharging cement at construction sites. Without proper support legs properly positioned during loading and discharging, the truck tips over, leading to a catastrophic accident.

The pedestal components are critical in ensuring the cement truck operates with stability and efficiency. A well-maintained hydraulic system, lubricated bearings, and properly positioned support legs are necessary for safe operation.

Pedestal Components

Cement trucks wouldn't be able to function without their pedestal components. They are the truck's base and consist of several essential parts responsible for its stability, movement, and rotation. Let's take a closer look at each of these components.

The Hydraulic System That Controls Pedestal Movement

The hydraulic system is one of the most crucial components of a cement truck's pedestal. It controls the movement of the pedestal, including raising and lowering it. The hydraulic system uses high-pressure liquid to generate force and move different parts of the truck's mechanism.

The hydraulic system is one of the most crucial components of a cement truck's pedestal. It controls the movement of the pedestal, including raising and lowering it. The hydraulic system uses high-pressure liquid to generate force and move different parts of the truck's mechanism.

Without it, it would be impossible to operate a cement truck. Most modern cement trucks use hydraulic systems lasting up to 10 years before needing replacement or repair.

However, it's essential to maintain them regularly to ensure optimal performance and longevity. Neglecting maintenance leads to leaks, worn-out seals, broken hoses, or damaged pumps.

The Bearings That Allow for Smooth Drum Rotation

Another critical component of a cement truck's pedestal is its bearings which allow smooth drum rotation. Bearings are small metal balls or rollers placed inside races or rings on both sides of an object that rotates around an axis like a wheel or drum.

In cement trucks' case, bearings sit at both ends of the drum axle and support its weight while allowing it to rotate freely in either direction during transportation or mixing operations. Without well-maintained bearings, cement trucks' drums may not turn as efficiently as they should during operation, leading to uneven mixing results.

The Support Legs That Stabilize The Truck During Operation

The support legs are integral parts located on either side under each end corner at the rear end frame opposite each other from where operators control them hydraulically from inside near the cab area with support leg control switches. They stabilize the truck during operation by allowing it to remain stationary when parked or loading and unloading. Support legs also provide additional stability for the entire truck when it's in mixing mode, making it less susceptible to tipping over or falling during uneven terrain usage.

Most support legs are fitted with sensors that detect any slight movement or shift in the truck's weight distribution, alerting drivers to take appropriate action quickly. However, like all other components of a cement truck, support legs require proper maintenance and care.

Maintenance Tips for Pedestal Components

To ensure optimal performance and longevity of your cement truck's pedestal components, keep them well-maintained. Regular inspection and cleaning help identify minor faults before they become major issues that may lead to costly repairs or replacements.

You should also ensure that you lubricate all moving parts regularly using high-quality lubricants recommended by the manufacturer. Lubrication helps reduce friction between parts, thus minimizing wear and tear on them.

You should also ensure that you lubricate all moving parts regularly using high-quality lubricants recommended by the manufacturer. Lubrication helps reduce friction between parts, thus minimizing wear and tear on them.

Additionally, always use high-quality replacement parts whenever you need to replace any damaged components of your cement truck's pedestal system. Don't opt for cheap alternatives, as they may not be compatible with your machine and leads to further damage.

Drum Components

The Mix-Master: Blades Inside the Drum

The blades inside the cement drum are the heart of every cement truck. These blades rotate at high speed, ensuring that all the components in the drum are mixed thoroughly.

Typically, two types of blades are used in cement mixers: spiral blades and paddles. Spiral blades mix the ingredients by pushing them toward the center of the mixer while paddles lift and drop them repeatedly.

Each blade is designed to have a unique shape that helps it function efficiently, ensuring optimal mixing. Some high-end cement trucks even come with adjustable blade configurations to ensure perfect mixing for different types of construction materials.

Water Tank: The Lifeblood of Cement Mixing

Water is essential in mixing cement; without it, you can't create concrete. Every cement truck has a water tank where water is stored and transported to construction sites for mixing with cement. The tank sits above or below the mixer drum and typically holds 400-800 gallons of water.

Water is essential in mixing cement; without it, you can't create concrete. Every cement truck has a water tank where water is stored and transported to construction sites for mixing with cement. The tank sits above or below the mixer drum and typically holds 400-800 gallons of water.

The water tank is designed to be durable and withstand harsh environments since it's constantly exposed to weather elements such as rain or hot sun rays during transportation or operation. A good quality valve ensures water flows smoothly when needed, preventing leaks and wastage.

Chute: Dispensing Cement at Construction Sites

Once mixed, concrete needs to be dispensed at construction sites—where chutes come into play—they act as channels through which concrete flows out from the mixer onto a designated spot on site.

Chutes vary in size depending on their intended use; some are narrow, while others are wide enough to quickly dispense larger concrete volumes. Quality chutes are made from durable materials such as stainless steel or aluminum alloy, making them long-lasting despite frequent use.

One critical aspect of chutes is cleaning- keeping them clean ensures the concrete flows smoothly without blockages. It's crucial to clean the chute after every use, removing any remaining concrete before it dries, which may cause blockages later.

Chassis Components

Cement trucks comprise several critical components; one of the most important is the chassis. The chassis supports all other components and is where they are all mounted. In this section, we will explore the components that make up the chassis and their importance in ensuring the optimal performance of cement trucks.

The Engine

The engine is a crucial component of any vehicle, and cement trucks are no exception. It powers the hydraulic system that controls the movement of the pedestal and drives the truck to transportation sites. The engine used in cement trucks must be powerful enough to handle heavy loads of cement without compromising performance.

The engine is a crucial component of any vehicle, and cement trucks are no exception. It powers the hydraulic system that controls the movement of the pedestal and drives the truck to transportation sites. The engine used in cement trucks must be powerful enough to handle heavy loads of cement without compromising performance.

When selecting an engine for a cement truck, manufacturers consider factors such as torque output, fuel consumption rate, and emissions control. Modern engines used in cement trucks are designed to be more environmentally friendly while maintaining high-performance levels.

The Transmission System

The transmission system transfers power from the engine to the wheels and controls speed. Cement trucks require robust transmission systems because of their heavy loads, which causes significant wear on these components.

The most common type of transmission system used in cement trucks is an automatic transmission with multiple gears, allowing for smooth shifting between gears while ensuring maximum power delivery to the wheels.

The Suspension System

The suspension system is responsible for absorbing shocks during transportation and providing a comfortable ride for drivers. Cement trucks require strong suspension systems because of heavy loads, causing significant wear on these components.

The suspension system used in a cement truck typically consists of springs or airbags that support the vehicle's weight and its load while reducing vibration during operation. Some newer models use hydraulic shocks instead of springs or airbags to provide better shock absorption qualities.

Conclusion

Cement trucks are integral equipment used in construction projects worldwide; hence their importance cannot be overstated. A well-maintained cement truck enables effective and efficient transportation of cement to construction sites while minimizing the risk of accidents and equipment breakdowns.

Regular maintenance should be a priority for companies that own or lease cement trucks to ensure the safety of drivers and passengers and optimize the vehicle's lifespan.