Curtain walls, an essential element in modern architecture, are the outer coverings of a building, protecting it from inclement weather and enhancing its aesthetic appeal.

They are non-structural and do not carry any load from the building other than their weight.

Curtain Walls

The term Curtain Wall was derived from the idea that the wall is as thin and hanging as a curtain. These walls, made predominantly of lightweight materials such as glass, provide a sophisticated and high-tech appearance to structures, accentuating their prominence in urban landscapes.

These façades protect buildings from the elements, allowing natural light and panoramic views, acting like an envelope, shielding the building's interior.

While they initially were glass, technological advancements have introduced various types of curtain walls, including metal panels, louvers, and stone veneers.

Curtain walls are an essential component of modern architecture that provides a striking visual appeal to a building. These walls are made up of various materials, including glass, aluminum, and steel, to name a few.

Among these materials, metal fabrication is crucial in creating diverse curtain walls that look aesthetically pleasing and serve practical purposes.

Metal Fab's Role

Metal fabrication creates metal frames for curtain walls supporting the weight of the glass panels and withstand strong winds and other environmental factors.

Metal fabrication allows intricate designs and patterns to be incorporated into the metal frames, enabling architects and designers to create unique and visually appealing curtain walls.

To summarize, metal fab's role in curtain walls includes:

- Creates metal frames supporting the weight of glass panels

- Withstands strong winds and other environmental factors

- Allows intricate designs and patterns for unique, appealing curtain walls

- Combines practical utility and artistic creativity

Combining practical utility and artistic creativity makes metal fabrication a vital aspect of modern architecture and construction.

Protective Coatings

Protective coatings play a key role when fabricating curtain walls, such as:

- Protective coatings provide a uniform finish with durability against extreme climates and corrosion

- E-coating: Electrical current deposits paint onto metal surfaces.

- Powder coating: Ecologically advantageous, no harmful VOCs, minimal waste.

Another factor to consider when fabricating a curtain wall is e-coating, a technique involving electrical current to deposit paint onto metal surfaces.

The result is a uniquely uniform finish providing long-lasting durability against extreme climates and corrosion, an excellent choice for high-performance curtain walls.

Powder coating has grown popular because of its ecological advantages over traditional liquid coatings: virtually no harmful VOCs emitted during the process nor waste generated.

Architectural Embeds

Embed steel parts are crucial for securing the curtain wall system to the building structure.

Well-designed architectural curtain walls successfully balance aesthetics with performance. Precisely engineered and fabricated embeds must fulfill requirements for thermal efficiency, light control, and sound insulation while remaining steadfast against wind forces, seismic activities, and other environmental factors.

4 Kinds of Curtain Walls

4 Kinds of Curtain Walls

Curtain walls exist in several forms, each with features tailored to meet the needs of diverse architectural designs and climatic conditions.

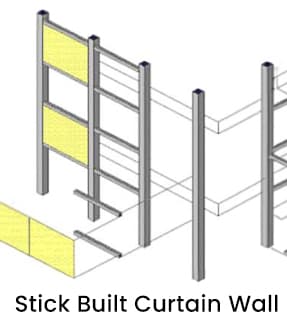

Stick-Built

The first type, stick-built curtain walls, are assembled piece by piece on the construction site.

They represent a meticulous and labor-intensive approach where individual mullions, vertical or horizontal divisions in the wall, and glazing panels are installed one after another on-site.

Mullions are custom-made to fit specific project requirements.

Mullions are custom-made to fit specific project requirements.

Unitized Curtain Walls

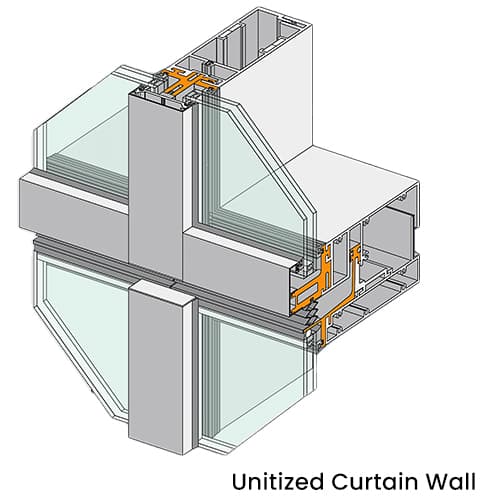

The second type is known as unitized curtain walls.

These systems dramatically reduce the on-site labor needed for assembly because they are fabricated off-site.

Each section is pre-glazed and sometimes even pre-insulated before reaching the construction location, allowing for faster closure of the building envelope against adverse weather conditions.

For these systems, durability is often enhanced through powder coating or e-coating applications, which provide increased resistance against corrosion.

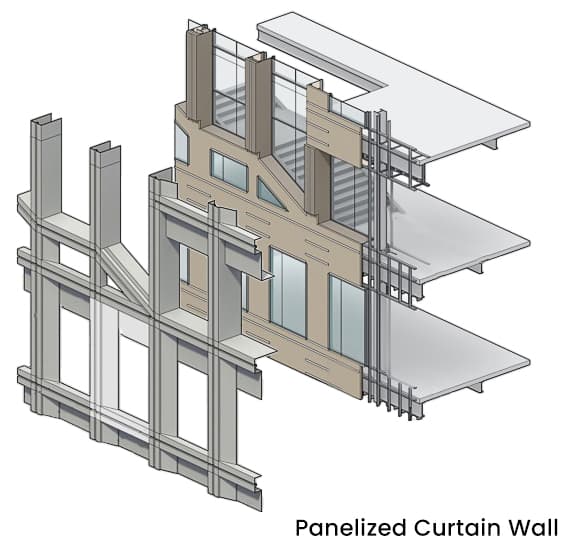

Panelized

Another prominent type is panelized curtain walls that compromise individual large panels with integrated windows installed between floors of a building structure.

Another prominent type is panelized curtain walls that compromise individual large panels with integrated windows installed between floors of a building structure.

These panels often use embeds to attach points to structures, offering superior structural support while maintaining aesthetic consistency.

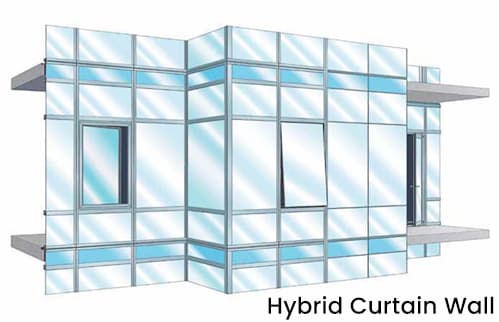

Hybrid

Hybrid curtain wall systems combine elements from other types. Hybrids ensure versatile adaptability according to project needs and mitigate potential pitfalls in each system individually.

These curtain wall systems may feature various finishes, such as powder coating or e-coating, and embeds for enhanced structural integrity, making them an enticing choice for architects seeking greater design flexibility.

These curtain wall systems may feature various finishes, such as powder coating or e-coating, and embeds for enhanced structural integrity, making them an enticing choice for architects seeking greater design flexibility.

These diverse types illustrate how curtain wall systems have evolved into intricate architectural tools custom-fitted to serve specific functions while actively shaping a building's visual identity.

Performance Considerations in Building Construction

Curtain walls, as a prominent element of building construction, command a lot of attention on performance considerations. Curtain walls:

- Resist water and air infiltration

- Endure forces of wind loads

- Maintain structural integrity, energy efficiency, weather resistance, and acoustic control

These façades systems serve an aesthetic function and hold key performance responsibilities.

Weatherproofing on an Industrial Scale

Among the most critical functions is their ability to resist water and air infiltration while enduring the forces of wind loads.

Combining curtain wall systems with superior weather tightness is critical. The integrity of seals, gaskets, and glazing units plays a substantial role in ensuring water or moisture does not penetrate the interior spaces, causing potential damage to both structure and occupants' comforts.

Similarly, air infiltration needs to be minimized, requiring precise engineering involving the choice of materials for construction and finishes.

Fighting Mother Nature

Metallic elements used in curtain wall systems should be strong enough to bear wind loads without deforming. Metal fabrication ensures each part is tailored accurately for assembly into a unitized system that withstands high wind pressures common at higher floors of tall buildings.

Curtain walls must be designed considering thermal performance too.

Energy efficiency significantly increases when careful attention is paid to insulation within these exterior wall systems- reducing heat loss during winters and heat gain during summers.

Other Factors

Incorporating embeds into curtain wall design has also grown increasingly popular because of their structural benefits in load-bearing capacity, ease of installation, and compatibility with other facade elements such as mullions or transoms.

Acoustic performance cannot be overlooked either: it contributes to occupants' comfort levels within the building.

Overall, the performance considerations for curtain walls are wide in scope, encompassing structural integrity, energy efficiency, weather resistance, and acoustic control.

Energy Efficiency Contributions

Curtain walls serve as an intricate interface between the interior and exterior environment. The roles they play include:

Curtain walls serve as an intricate interface between the interior and exterior environment. The roles they play include:

- Regulating heat transfer to maintain optimal internal conditions

- Precision in metalworking for detailed customization

- Surface treatments like powder coating and e-coating enhance thermal performance

Hyper Metal Fab Work

Metal fabrication is integral to this process. The precision of contemporary metalworking techniques allows for detailed customization of curtain wall components, ensuring a snug fit, reducing air infiltration, and enhancing thermal performance.

Diverse metals such as aluminum or steel are formed and welded into complex, high-performance systems that bring about aesthetic appeal and contribute critically towards minimizing energy consumption.

However, the effectiveness of these components depends largely on their surface treatment, such as powder coating and e-coating.

Protecting the Metal That Protects Buildings

These coatings function as more than just superficial decorations; they provide crucial protection against harsh environmental conditions, which could compromise the integrity of the curtain wall system.

Powder coating creates a resilient external layer over the metal parts used in curtain walls.

This layer serves dual purposes:

- Adds color and texture to fulfill aesthetic requirements

- Shields components from corrosion or other forms of degradation

By enhancing durability and maintaining functionality over extended periods, powder coating contributes significantly to overall energy-efficient performance.

E-coating or electrocoating ratchets this protective function up a notch by providing an even more thorough coverage than traditional painting or powder-coating methods.

By fully immersing the metal components in a liquid-based solution containing particles charged with electricity, every nook, cranny, and complex shape is uniformly coated—ensuring heightened resistance against wear-tear and corrosion while extending lifespan substantially.

Together, these processes ...

- Embedding insulation materials into design elements during the construction phase

- Prefabricated metalwork delivering high-precision fitting

- Innovative surface treatments such as powder coating or e-coating

... combine to enhance the thermal performance of curtain walls

... combine to enhance the thermal performance of curtain walls

They elevate buildings from mere structural entities to intelligent, energy-efficient systems that respond optimally to their environment, proving that behind the sleek exterior of these glass and steel marvels lies a meticulously planned strategy for efficient energy use.

Fun Fact: Oriel Chambers

Built in 1864 and designed by architect Peter Ellis, Oriel Chambers is the world's first building featuring a metal framed curtain wall. Located at 16 Cook Street, Liverpool, England, the office building became the first example of what businesses could look like. Its curtain wall design became a defining feature of skyscrapers throughout the world.

In Sum

Curtain walls are much more than architectural adornments; they are pivotal in modern construction.

Understanding curtain wall design and performance fundamentals is integral to erecting strong structures against nature and contributes significantly to energy efficiency.

Image Sources