Optimizing your production process can be challenging as a manufacturer because of so many moving parts. Kitting is a process that involves grouping all the components and materials required for a particular manufacturing process, helping streamline your workflow, and reducing the time taken to complete each step of the production process.

What is Kitting?

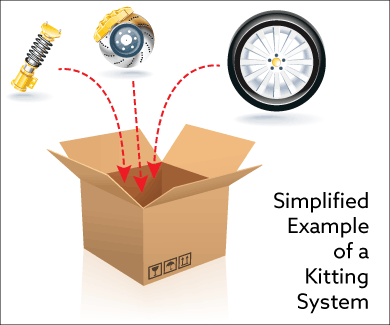

Kitting is the process of grouping all the components and materials needed for a particular manufacturing process. This includes raw materials, finished products, and any tools or equipment required to complete the process. Kitting can help to improve efficiency and accuracy in manufacturing, as well as reduce costs.

What is the difference between kitting, bundling, and assembly?

Kitting, bundling, and assembly are three different manufacturing and supply chain management processes.

- Kitting involves grouping individual components or parts in a package or kit, usually with a specific purpose—helping simplify the assembly process and reduce the time needed to find and organize individual parts.

- Bundling typically involves grouping several related items for ease of handling and transport. The items in a bundle may not necessarily be all the components needed to complete a particular task or product.

- Assembly involves assembling individual parts or components to create a finished product, which may involve using tools, machinery, or manual labor to assemble the various parts or components in the correct order and configuration.

Using the three processes together improves the efficiency and effectiveness of manufacturing and supply chain management.

Benefits of Kitting in Manufacturing

Kitting provides several benefits in the manufacturing process, including:

Kitting provides several benefits in the manufacturing process, including:

Overall, kitting benefits manufacturers significantly, helping streamline their operations, reduce costs, improve quality control, and enhance customer service.

Benefits of Assembly in Manufacturing

Assembly plays a crucial role in the manufacturing process, providing several benefits, including:

- Efficient Production: Assembly enables manufacturers to produce large quantities of products quickly and consistently. By utilizing automation and efficient assembly processes, manufacturers can minimize production time, reduce labor costs, and increase output.

- Consistency and Quality Control: Assembly processes often involve quality control measures to ensure each product meets the required quality standards, helping minimize defects, reducing waste, and improving overall product consistency.

- Customization: Manufacturers can easily customize assembly processes to meet the unique needs of each product or customer by changing the assembly process to accommodate different materials, sizes, and specifications, allowing them to offer a wide range of products to their customers.

- Improved Safety: Assembly processes often involve using specialized equipment, tools, and safety procedures to ensure the safety of workers and minimize the risk of workplace injuries.

- Cost Savings: Assembly can provide cost savings by reducing the labor required to produce products, increasing efficiency, minimizing waste, passing these savings on to customers, and making products more affordable and accessible.

Overall, assembly is a critical component of the manufacturing process, providing many benefits, including efficient production, consistent quality control, customization, improved safety, and cost savings.

What types of industries commonly use kitting?

Several industries use kitting to simplify inventory management and reduce assembly time.

Here are five types of industries that commonly use kitting, along with examples of how they do it:

- Original Equipment Manufacturers: OEMs use kitting to prepare components and materials needed for production. For example, in the automobile industry, kitting groups all the parts needed for a particular car model, such as engine components, electrical parts, and other accessories.

- Aerospace: The aerospace industry uses kitting to prepare the components and tools needed for aircraft maintenance and repair. For example, kitting groups all the tools needed for a particular maintenance job, such as engine maintenance or avionics repairs.

- Healthcare: The healthcare industry uses kitting when preparing medical kits and trays for surgical procedures. For example, hospitals use kitting to group all the medical equipment needed for surgery, such as surgical instruments, gloves, and gowns.

- Retail: Retail uses kitting when preparing products for sale. For example, in a clothing store, kitting groups all the items for an outfit, such as a shirt, pants, and accessories, making it easier for customers.

- Electronics: The electronics industry uses kitting when preparing components for assembling electronic products. For example, when making a computer, OEMs kit all the components needed to assemble a computer system, such as a motherboard, hard drive, and power supply.

How does kitting fit into the just-in-time production model?

Kitting is a critical component of the just-in-time (JIT) production model. JIT is a manufacturing philosophy aiming to minimize waste and increase efficiency by producing goods only as needed in the production process. The goal is to reduce inventory levels and associated costs while increasing responsiveness to customer demand.

By preparing these kits ahead of time, manufacturers reduce the time and effort required to retrieve materials during production, which helps reduce overall production time and costs.

Different Types of Kitting

There are different types of kitting based on component packaging, the kit's purpose, and the stage of the manufacturing process in which the kitting takes place. Here are some common types of kitting:

- Pre-Assembly Kitting: In this type of kitting, the components needed for a particular assembly or sub-assembly are grouped and packaged together before the assembly process begins, which helps to streamline the assembly process and reduce the time required to search for individual components.

- Bulk Kitting: This type involves packaging a large number of components together in a single kit, which may contain enough components to produce multiple units of a product, or it may contain all of the components needed for a single product. Bulk kitting is useful when manufacturing the same product in large quantities.

- Just-in-time (JIT) Kitting: (as explained above) JIT kitting is assembling and packaging components just in time for the assembly process, which helps to reduce inventory costs and improve manufacturing efficiency, as it ensures that only the necessary components are available when needed.

- Service Kitting: Service kitting involves packaging spare parts and tools to maintain and repair equipment or machinery. Service kits are typically pre-packaged and stored until needed, making it easy to perform maintenance or repairs quickly.

- Retail Kitting: Retail kitting involves packaging products and accessories to create a complete product package sold to customers. For example, a camera kit may include a camera, lens, memory card, and carrying case.

- Point-of-use (POU) Kitting: In POU kitting, the components are packaged and delivered to the point of use, such as a specific workstation on the assembly line. This type of kitting reduces the time and effort required to move components from a central inventory location to the point of use.

These are just a few examples of the types of kitting that exist. The specific type of kitting used depends on the needs of the manufacturing or logistics process.

In Sum

Kitting is a process used in manufacturing that involves grouping all the components and materials required for a particular manufacturing process, from raw materials to finished products, and any tools or equipment required to complete the process.

Kitting helps streamline the workflow, reducing the time taken to complete each step of the production process, and provides several benefits, such as improved efficiency, reduced costs, improved quality control, flexibility, and enhanced customer service.