The word "revolution" is used in several ways, such as in sociological and mechanical terms. Sociologically speaking, a revolution is defined as:

A radical and pervasive change in society and the social structure, especially one made suddenly and often accompanied by violence.

Thankfully, changes are not as radical or sudden when people talk about the four industrial revolutions. Instead, the revolutions we are discussing represent a complete change that took place over many years.

Now, we are in Industry 4.0.

What is Industry 4.0?

Industry 4.0, in general terms, illustrates increasing trends toward data exchange and information in processes and technology within the manufacturing sector. The technologies used in 4.0 include:

- The Internet of Things (IoT)

- The Industrial Internet of Things (IIoT)

- Cyber-physical systems (CPS)

- Smart manufacture

- Smart factories

- Cloud computing

- Cognitive computing

- Artificial intelligence

This automation creates a manufacturing system whereby factory machines are augmented with wireless connectivity and sensors to monitor and visualize an entire production process and make autonomous decisions.

With the full rollout of 5G, wireless connectivity and machine augmentation will be advanced. These upgrades will provide faster response times, allowing for near real-time communication between systems.

With the full rollout of 5G, wireless connectivity and machine augmentation will be advanced. These upgrades will provide faster response times, allowing for near real-time communication between systems.

Another aspect of using Industry 4.0 relates to using Digital Twin Tech:

A digital twin is a digital representation of a physical object, process, or service. A digital twin can be a digital replica of an object in the physical world, such as a jet engine or wind farm, or even larger items, such as buildings or entire cities.

As well as physical assets, the digital twin technology replicates processes to collect data to predict how they will perform.

While every organization and company operating today are different, they all face common challenges and the need for connectivity and access to real-time insights across products, processes, people, and partners.

Industry 4.0 is not just about spending money on new technology and tools to develop manufacturing productivity; it is about modernizing how your entire business grows and operates. The world of manufacturing is changing.

Our Industrial Revolutions

By experiencing Industry 4.0, we assume there were three previous revolutions:

By experiencing Industry 4.0, we assume there were three previous revolutions:

Industry 1.0

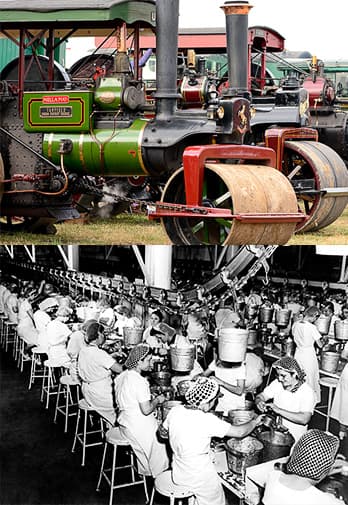

The leading industrial revolution occurred between the 1700s and early 1800s. Manufacturing developed from concentrating on labor-intensive and aided by work animals to a more optimized form of delivery completed by people through water and steam-powered engines and other types of machine tools.

Industry 2.0

In the earlier 20th century, the world entered the Industry 2.0 revolution by introducing steel and electricity in factories. The addition of electricity assisted manufacturers in increasing efficiency and helped factory machinery be more mobile. During this phase, mass production concepts, such as the assembly line, were introduced, boosting productivity.

Industry 3.0

The Industry 3.0 revolution slowly emerged in the late 1950s as manufacturers started incorporating more electronic and, eventually, computer technology into their plants. Manufacturers began facing a shift that placed less stress on mechanical and analog technology and more on automation software and digital technology.

Industry 4.0

The Industry 4.0 revolution emerged in the past few decades. It emphasized current digital technology and raised it to a top level with the support of linkage through the Industrial Internet of Things (IIoT), introducing cyber-physical systems and access to real-time data.

Industry 4.0:

- Gives a more holistic, interlinked, and comprehensive approach to business. It allows for better partnership and access across partners, departments, vendors, people, and products.

- Enables business owners to understand better and control every part of their operation and leverage primary data to drive growth, boost productivity, and improve processes.

Using 4.0

One way to understand the concept of IIoT, or smart manufacturing, is by thinking about how you can relate it to your business. Here are three ways to use the concept of Industry 4.0 in your business operation:

Asset Tracking and Optimization

Industry 4.0 solutions help industrialists become more competent with assets at each phase of the supply chain, keeping a healthier pulse on optimization, inventory, and quality opportunities involving logistics.

With the Industrial Internet of Things ready at a workshop, employees attain better visibility worldwide. They streamline and manage standard asset organization tasks such as real-time adjustments, asset transfers, disposals, and reclassifications.

Predictive Analytics/Maintenance

Predictive analytics permits companies to not just ask reactive questions like, "What happened?" but proactively ask, "What's going to happen," and "How can we stop it from happening?" These kinds of analytics allow manufacturers to swivel from preventive conservation to predictive conservation.

Industry 4.0 solutions provide manufacturers with the talent to predict when potential problems arise before they happen. When facilities do not take advantage of IIoT, preventive maintenance occurs based on schedules.

When using the technology available with the IIoT, preventative care is much more streamlined and automated. Systems detect problems in real-time, solving potential problems before they become more significant.

Supply Chain Management and Optimization

Supply Chain Management and Optimization

Industry 4.0 solutions offer businesses superior control, insight, and data visibility through their complete supply chain.

By influencing supply chain management proficiencies, companies can convey goods and services to bazaar cheaper and faster, with better value, to benefit fruitless competitors.

Advantages of 4.0

Industry 4.0 widens the complete supply chain and product life cycle, including customer and field service, design, sales, inventory, engineering, scheduling, and quality.

Everyone shares up-to-date, informed, relevant views of business and production processes and much more affluent and timelier analytics.

Here is a list of rewards of embracing an Industry 4.0 model for your industry:

- Attractive: Establishments that invest in contemporary, advanced Industry 4.0 technologies can entice and keep new workers.

- Stronger Teams: Companies that capitalize in Industry 4.0 can increase efficiency, enhance collaboration among departments, enable prescriptive and predictive analytics, and tolerate people, including executives, operators, and managers, to more completely leverage intelligence and real-time data to make better verdicts while managing their daily tasks.

- Fix Problems Early: Predictive analytics, real-time data, internet-connected machinery, and automation can help you be more proactive in addressing and solving likely maintenance and supply chain management issues.

- Streamlines: Industry 4.0 technology helps you optimize and manage all aspects of your supply chain and production processes. It gives you access to the insights and real-time data you want to make faster, smarter decisions about your trade, which can eventually boost your entire operation's efficiency and profitability.

Overcoming Challenges

As you consider investing in Industry 4.0, there are potential challenges. Here are some of the most common challenges manufacturers face while starting 4.0:

- Date Security: Companies devoted to cloud-based services need assurances their proprietary information is secure.

- Team Support: Convincing employees to buy-in is a hard task.

- Resource Availability: The beginning of Software as a Service (SaaS) eliminates heavy reliance on internal IT departments. SaaS companies perform maintenance and updates needed, leaving IT departments to work on other projects.

Looking Ahead

The headline sounds like a movie sequel: Industry 5.0: The Return of the Human Touch. 5.0 allows a better automation process for manufacturing while also providing real-time incoming information. Where 4.0-reduced the need for people, 5.0 brings them back.

The headline sounds like a movie sequel: Industry 5.0: The Return of the Human Touch. 5.0 allows a better automation process for manufacturing while also providing real-time incoming information. Where 4.0-reduced the need for people, 5.0 brings them back.

Universal Robots' chief technology officer and co-founder Esben Østergaard classifies Industry 5.0 in a most peculiar way.

This Industry 5.0 trend is more anti-industrial than industrial. It is a return to something earlier, to a time before industrialization, when a gift, for example, was something someone you knew spent months knitting, carving, or creating by hand. It was just for you because the person who made the gift knew you personally and thus knew how to make a gift for you and no one else.

Most importantly, the mass customization described above and enabled by Industry 4.0 is not enough. Because consumers want more. They want mass personalization, which can only be had when the human touch returns to manufacturing. This is what I call Industry 5.0.

Østergaard believes that collaborative robots will not replace humans. Instead, they will enhance craftsmanship, providing the precision, speed, and accuracy needed for modern products.

In Sum

Like Earth's rotation around the sun, industrial revolutions are inevitable. We have barely scratched the surface of Industry 4.0, and it seems 5.0 is right around the corner.

Until that fifth revolution occurs, taking advantage of available tools from Industry 4.0 provides sensational benefits. As with anything new, there is risk involved. As they say, no risk, no reward.