In manufacturing, companies are finding themselves busier than they have been in years. The sheer number of jobs queued up in their production schedules are now overwhelming companies.

With such demands on the lead time, it magnified any inefficiencies in their processes, potentially creating longer lead times and quality issues.

Situations like this are where strategies like Quick Response Manufacturing (QRM) shine.

QRM: a Quick Recap

We've previously described QRM:

Quick Response Manufacturing focuses on reducing lead and delivery times. This focus results in decreased production costs. The reduction in hidden costs is because of the reduced working process, fewer mistakes, and fewer customer complaints because of late deliveries.

Customer satisfaction is one of the driving forces behind QRM. Fast response to customer requirements is vital. This response gives companies a competitive advantage by delivering products at reduced prices.

QRM analyzes how machines, people, and products interact to affect lead times. They apply it during planning for materials and control, office operations, purchasing, and supply chain management.

The benefits of using QRM as a strategy are undeniable:

The concept of quick response manufacturing (QRM) is a strategy of cutting lead times in all aspects of manufacturing operations. When implemented, a QRM program:

- 95% reduction of lead times

- 30% reduction of the finished product cost

- 60% improvement in on-time delivery

- 80% reduction of rework and scrap

Two types of businesses use a QRM:

- A company producing a small batch of engineered materials

- A company that doesn't need to engineer products, but offers many original pieces with varying demand

Manufacturing Critical-path Time

The driving force behind QRM's effectiveness is frighteningly simple: increasing the touch time of components during the manufacturing process.

The driving force behind QRM's effectiveness is frighteningly simple: increasing the touch time of components during the manufacturing process.

Time is money. When examining the journey components take through a manufacturing company's production schedule, several incidents occur when an RFQ arrives. The entire process of that quote becoming a job sits in inboxes. Although that doesn't sound daunting, it adds up.

This is where mapping out the Manufacturing Critical-path Time shines.

Mapping

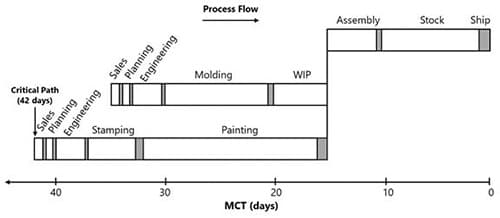

Creating an MCT map is a simple task, but it requires an honest evaluation of each step a component takes throughout the process flow. Look at the illustration below. It highlights two significant events throughout the journey: grey and white times.

Grey Time represent the period when a person is handling the piece. White Time represents non-added value times, such as sitting in an inbox.

Reviewing the MCT map highlights areas where a company re-prioritizes its efforts, making the first step towards lead-time reduction.

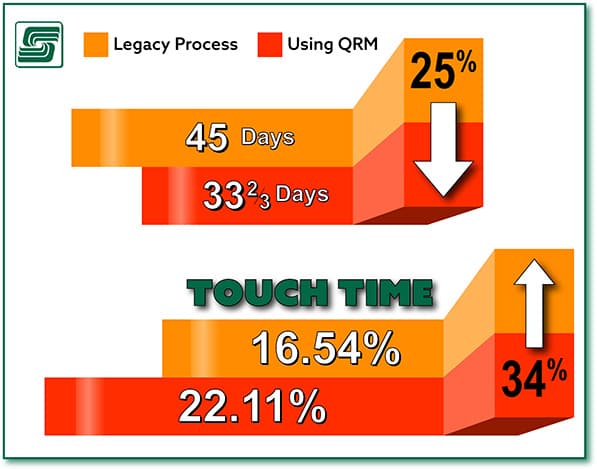

We recently proved QRM's effectiveness by testing a project that traveled through our shop. After collecting the data, the results were significant! Look at the image below. Using QRM, we knocked nearly 11-1/2 days off our process time by increasing touch time by 34%.

We recently proved QRM's effectiveness by testing a project that traveled through our shop. After collecting the data, the results were significant! Look at the image below. Using QRM, we knocked nearly 11-1/2 days off our process time by increasing touch time by 34%.

In Sum

Every journey becomes easier when you can see where you're heading. Using a GPS helps navigate to your vacation hideaway. Using the QRM strategy, the MCT helps identify the best route to take in reducing lead times.

Having the right tools, and more importantly, knowing how to use them leads to success. Starting your QRM process doesn't have to be complicated. There are tools out there to help you along the way.