Technology's continuous advancement has changed the manufacturing industry by transforming every aspect of production lines and supply chains worldwide. From introducing steam-powered machinery during the Industrial Revolution to developing CNC systems in recent years, technology has consistently increased productivity, reduced labor costs, and improved quality.

Now, we are seeing a new phase in this technological evolution, characterized by digitalization and automation. Industry 4.0 merges cyber-physical systems with IoT and cloud computing to create smart factories. Sophisticated software systems are employed for anything, including inventory management and predictive maintenance. Artificial intelligence algorithms optimize operations; collaborative robots or cobots work side-by-side with humans; and additive manufacturing techniques like 3D printing create prototypes faster than ever.

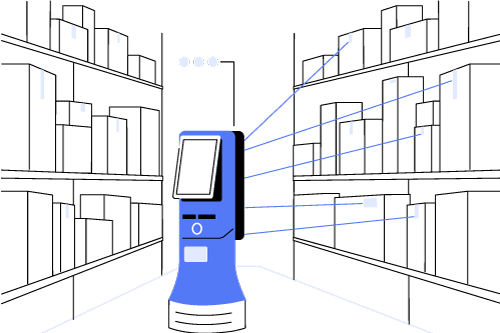

Another technological achievement, Autonomous Mobile Robots (AMRs), is included in all these innovations.

Meet Autonomous Mobile Robots

Autonomous Mobile Robots have emerged as a revolutionary tool in the bustling industrial automation ecosystem. These sophisticated machines can be programmed to navigate an uncontrolled environment without needing guidance devices.

Autonomous Mobile Robots have emerged as a revolutionary tool in the bustling industrial automation ecosystem. These sophisticated machines can be programmed to navigate an uncontrolled environment without needing guidance devices.

Unlike traditional Automated Guided Vehicles (AGVs), which require wires, magnets, or markers for navigation, AMRs autonomously decide their path based on their surroundings.

This autonomy is achieved through several technologies, such as cameras, lidar sensors, and sophisticated onboard computing power. AMRs manage material handling and transportation within a facility without human intervention.

These robots are built with advanced sensors and machine learning algorithms, allowing them to understand their environment and decide accordingly. They maneuver around obstacles in real time while ensuring the safety of personnel working nearby.

The versatility of AMRs extends far beyond moving materials from one spot to another; they also pick items from shelves, assemble components, and even perform inspections.

Here are some of the key benefits of AMRs in manufacturing:

- Increased efficiency: AMRs can work 24/7 without breaks and navigate complex environments without getting lost [2]. This means they automate tasks that people would otherwise perform, who need to take breaks and can make mistakes.

- Improved productivity: AMRs can move materials and products faster than humans. This means they help reduce production time and increase output.

- Enhanced safety: AMRs can be programmed to avoid obstacles and people, which can help to reduce the risk of accidents. They also perform hazardous tasks, such as lifting heavy objects or working with dangerous chemicals.

Key Functions and Capabilities

With an ever-increasing demand for efficiency and swift execution, AMRs have played a pivotal role in modern manufacturing facilities.

Their core functions revolve around material transportation, assembly help, inspection, and data collection; however, their capabilities extend beyond this scope.

Independent Navigation

AMRs are proficient in navigating independently across complex industrial landscapes without supervision.

For instance, their distinctive function is transporting raw materials or finished products on the shop floor.

Advanced Sensors

AMRs have advanced sensory systems that facilitate accurate object detection and manipulation, making them effective in assembly help.

Inspections

Regarding inspection tasks, such as quality checks or safety audits within the manufacturing arena, AMRs have proven invaluable assets.

AMR Advantages

Autonomous Mobile Robots have revolutionized manufacturing, enhancing productivity and efficiency. Their integration into the industrial system provides many benefits for achieving optimal performance.

Autonomous Mobile Robots have revolutionized manufacturing, enhancing productivity and efficiency. Their integration into the industrial system provides many benefits for achieving optimal performance.

Adaptable Navigation

Their versatility and adaptability allow these robots to navigate complex environments, eliminating the need for fixed pathways or difficult manual operations.

Scalability

AMRs offer scalability: something crucial in a fast-paced, progressive manufacturing environment. They can be easily added or removed from the production line as demand fluctuates, ensuring the system can handle varying workloads effectively.

Adaptability

Their modular nature allows them to adapt to volume or production requirements changes.

Taking on the Hazardous Tasks

AMRs significantly improve resource use within manufacturing facilities by efficiently managing raw materials and finished goods with precision and without waste. This management results in reduced material costs and an increase in overall operational effectiveness.

Adopting AMR technology translates into a smaller environmental footprint from increased efficiency and reduced waste.

Challenges of Implementation

While beneficial, integrating autonomous mobile robots into manufacturing operations poses a unique set of challenges.

Initial Setup and Integration

One such challenge is the initial setup and integration process. These advanced robotic systems require careful calibration and testing to integrate existing systems and people seamlessly.

Uncertainties in Unpredictable Environments

The unexpected behaviors of AMRs in unpredictable situations or how workers adapt to these automated assistants also present challenges in implementation.

Overcoming Challenges and Embracing the Future

Despite these challenges, the advantages of AMRs far outweigh the drawbacks. AMRs will become even more sophisticated, adaptable, and integrated into manufacturing operations as technology advances.

In Sum

AMRs are poised to revolutionize the manufacturing industry, ushering in a new era of efficiency, safety, and productivity. By embracing this transformative technology, manufacturers can achieve operational excellence, enhance product quality, and gain a competitive edge in the global marketplace.

Autonomous mobile robots (AMRs) are transforming the manufacturing industry by automating tasks previously performed by humans. Their implementation increases efficiency, productivity, and safety.